DRILLED PIERS AND IT’S CONSTRUCTION

A drilled pier is a deep foundation system that is a large diameter concrete cylinder constructed by placing fresh concrete and reinforcing steel into a drilled shaft. It is also called as caissons, drilled shafts, drilled piers, Cast-in-drilled-hole piles (CIDH piles) or Cast-in-Situ piles.

For construction of drilled pier, a large diameter hole is drilled in the ground and filled with concrete subsequently. The difference between a drilled pier and bored pile is basically of the size. Generally, bore piles are of diameter less than or equal to 0.6m.the shafts of size larger than 0.6m are generally designated as drilled piers. A drilled pier is a type of deep foundation constructed to transfer heavy axial or lateral loads to a deep stratum below the ground surface.

Construction of drilled piers:

The construction of drilled piers involved in below 3 stages.

- Excavation of piers

- Providing supports

- Concreting

Excavation of piers:

1. Generally auger drill is used mostly for the excavation of drilled pier. Other type of drilling equipment are also there.

2. An auger is attached to a shaft and rotated under pressure to dig into the soil. When it is filled with soil, it is raised above the ground and emptied.

3. When the soil stratum does not having adequate bearing capacity belled piers are generally used. For formation of a bell, the auger is replaced by an under reaming tool which consists of a cylinder with cutting blades that are hinged at top.

Fig: Under reaming tool

4. The cutting blades are in the folded position when the under reamer is lowered into the hole. On reaching the bottom of the hole, the blades are spread outward by a mechanism.

5. As the under reamer is rotated, a bell is formed and the loose soil falls inside the cylinder, which is raised and emptied. The process is repeated until the bell is completely formed. The diameter of the bell is kept two to three times the diameter of the shaft. The angle of the bell is 30o to 45o with the vertical.

6. The above method of drilling is convenient for hard clays where the hole can be left open for a few hours without a support. In cohesion less soils below the water table, the hole is prevented from collapsing by providing a casing or by drilling in slurry. When rock is encountered during drilling special machines are required.

Providing supports:

There are two methods available for providing supports.

- Chicago method

- Gow method

Chicago method:

In this method, a circular hole is excavated up to the depth at which the soil will stand unsupported (about 0.5m for soft clay and 2m for stiff clay). Vertical boards known as laggings, are then set in position around the excavated face and are held tightly against the soil by steel rings. The shaft is then excavated further for 1 to 2m and another setting of boards and rings is made. The process is repeated until the desired level is reached. The base of the shaft is then belled out.

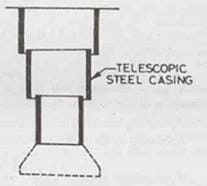

Gow method:

In this method excavation of hole is done manually. Telescopic steel shells are used to support the soil the telescopic shells are extended as the hole is deepened. The shells are removed as the concreting progress. One section of the shell is removed at one time. The minimum diameter of the hole in this method is about 1.25m.

Concreting piers:

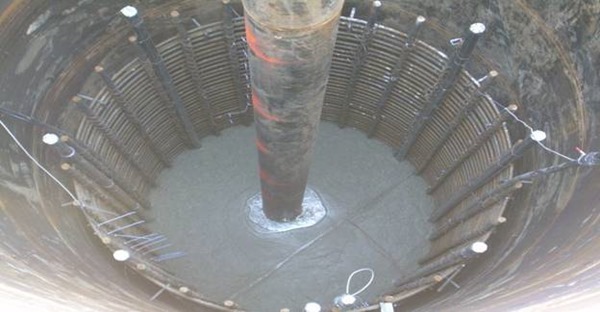

1. After the hole has been drilled to the required depth, the shaft is dewatered and the bottom is cleaned. The casing if used is removed.

2. The reinforcement cage is then inserted and concreting is done. As far as possible, concreting should be in dry.

3. Concreting can be done in a dry hole by gravity pouring, provided the concrete does not strike the sides. However, if dewatering is not possible or slurry is used to support the shaft sides, concrete is placed using a tremie.

Advantages of drilled piers:

1. A single drilled pier can take up the load of a group of piles.

2. They have higher resistance to lateral loads.

3. Compared to pile driving, equipment needed for drilled pier is lighter and there is no noise during construction.

4. Ground heaving do not exists in the case drilled piers.

5. Inspection of base and sides of pier is easier.

6. Base of drilled pier provides greater bearing capacity and great resistance to uplift.

7. They can be used even when the soil contains boulders.

Disadvantages drilled piers:

1. The concreting requires stricter supervision. The quality of concrete obtained is generally inferior to that in precast piles.

2. Deep excavation of drilled pier, if not properly supported, can cause substantial subsidence and damage to adjoining structures.

3. Load tests are difficult in case of drilled piers.

4. More subsurface investigations are required in case of drilled piers.

No comments:

Post a Comment